- 0 likes

- 27250 views

- 0 comments

A reader's experience report

Working with Redutex Foils

Our reader and book author Heribert Tönnies has studied the Redutex foils, which are also widely used in Z gauge, as an alternative for many other techniques. Today, he reports in particular detail on his experiences, which should also be of benefit to newcomers and those returning to the railways.

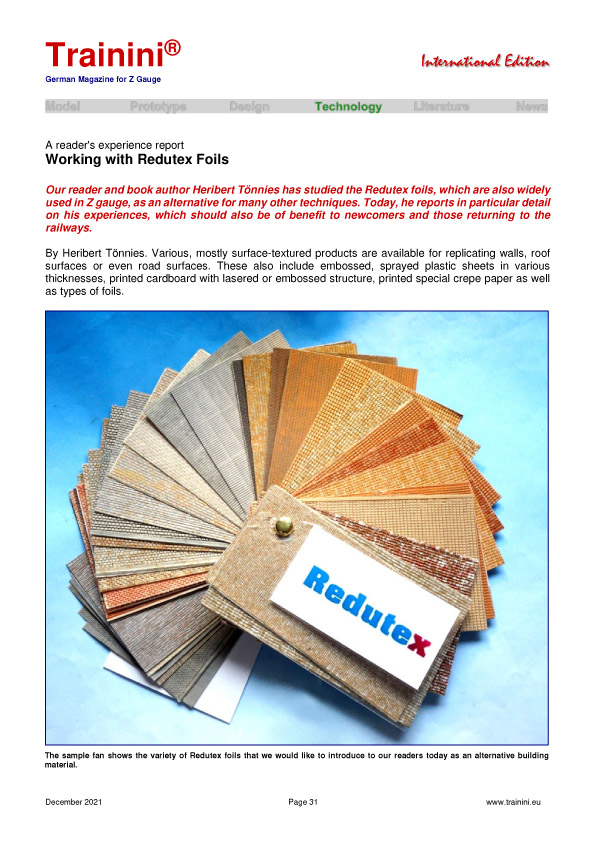

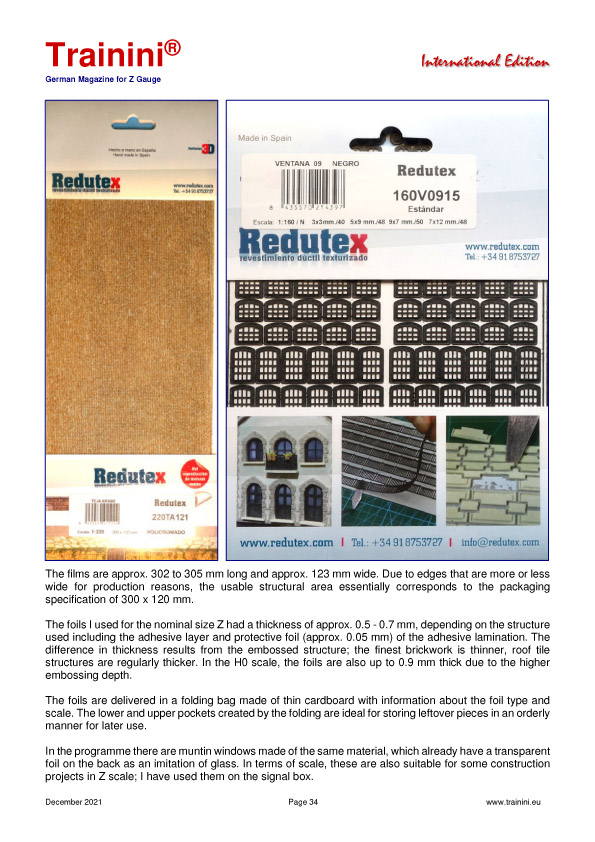

By Heribert Tönnies. Various, mostly surface-textured products are available for replicating walls, roof surfaces or even road surfaces. These also include embossed, sprayed plastic sheets in various thicknesses, printed cardboard with lasered or embossed structure, printed special crepe paper as well as types of foils.

Many of them also have a self-adhesive coating. Especially for road surfaces, for the sake of completeness, the so-called stamp/carrier rollers should also be mentioned, such as those offered by Modellbahn-Union or Microrama.

In addition to a different appearance, the individual materials have advantages and disadvantages, both in terms of processing and durability. Later changes cannot be ruled out, especially if the layout is used for a long time.

In my experience, over the years there has been considerable loss of quality, such as colour changes due to a lack of UV resistance. Incipient chemical processes caused foamed road films to become soft and even sticky-paste-like, and, thus, completely unusable.

Surfaces crumbled or the adhesive, which was partially applied to the back of the material and initially adhered well, changed over the years and led to detachment from the substrate, unless additional special bonding was carried out.

In contrast to the relatively easy processing of cardboard by simply cutting with scissors or knives, the thicker plastic sheets are already more demanding for the beginner without elaborate technical tools or pronounced manual skills, especially when the smallest components have to be worked out, or window openings have to be cut out.

Cardboard, for example, makes special demands on the formation of building corners due to the oftengreater thickness of the material, because the thickness of the material, if mitre cuts cannot be used due to the material, remains visible at the edge of the building without later lamination (filling or colour work), which can lead to unwanted effects, especially in a small scale.

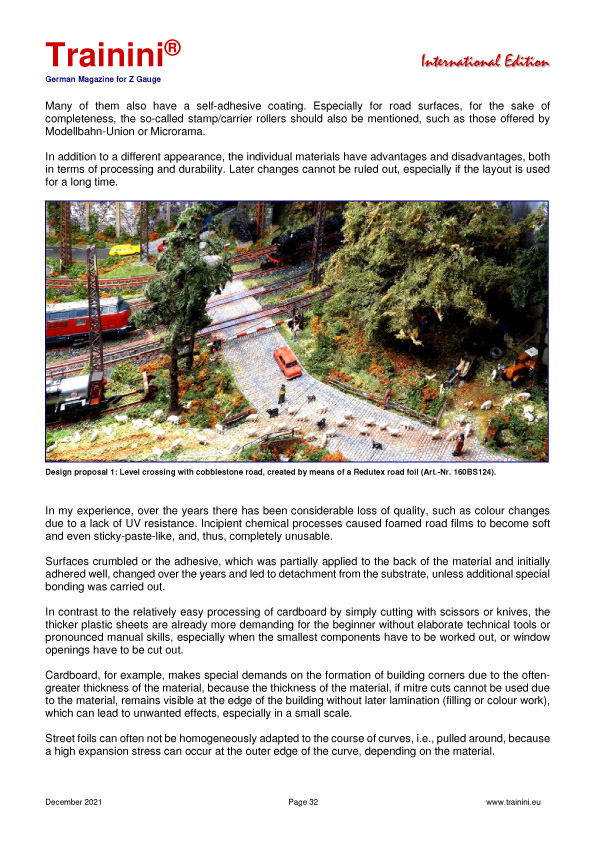

Street foils can often not be homogeneously adapted to the course of curves, i.e., pulled around, because a high expansion stress can occur at the outer edge of the curve, depending on the material.

It either impairs the shape of the road or prevents it from sticking to the substrate, while wrinkles form at the inner edge due to the compression. Circular segments must therefore be cut, the butt joints of which remain visible in some road construction materials without the need for time-consuming reworking.

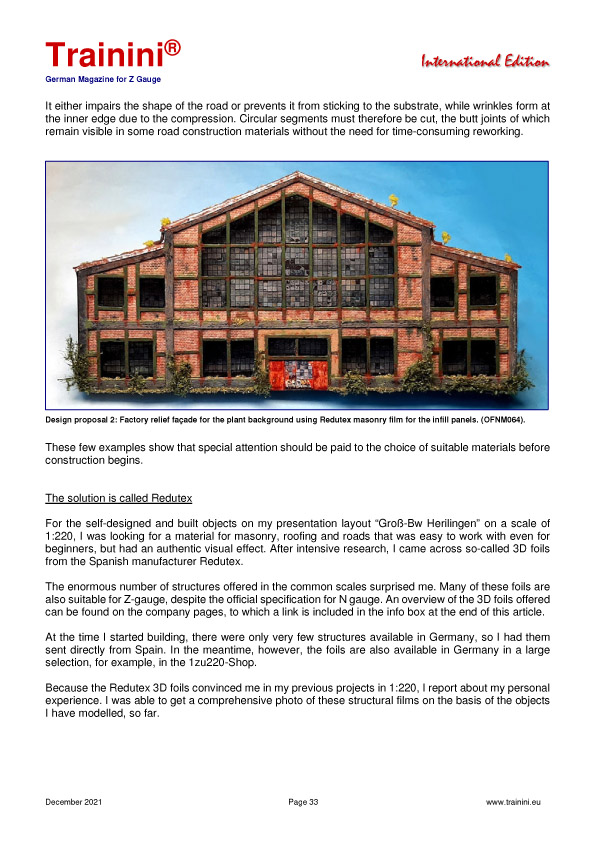

These few examples show that special attention should be paid to the choice of suitable materials before construction begins.

All photos: Heribert Tönnies

Comments (0)